Circuit breakers are core protection devices in electrical systems. Their main function is to cut off the circuit when overload, short circuit, or other faults occur, thereby preventing risks such as equipment damage and fire. According to the type of current, circuit breakers can be divided into direct current (DC) circuit breakers and alternating current (AC) circuit breakers.

There are significant differences between DC and AC circuit breakers in structural design, arc extinguishing principles, and application scenarios. Therefore, understanding the difference between the two and their respective advantages and disadvantages can better ensure the safe operation of electrical systems.

Table of Contents

ToggleDC circuit breakers

DC breakers are protective devices specifically designed for DC circuits. They are designed to handle overload or short circuit conditions that may occur in DC systems, preventing equipment damage or fire by quickly disconnecting the circuit. Since DC has no natural zero crossing, DC circuit breakers need to have stronger arc extinguishing capabilities.

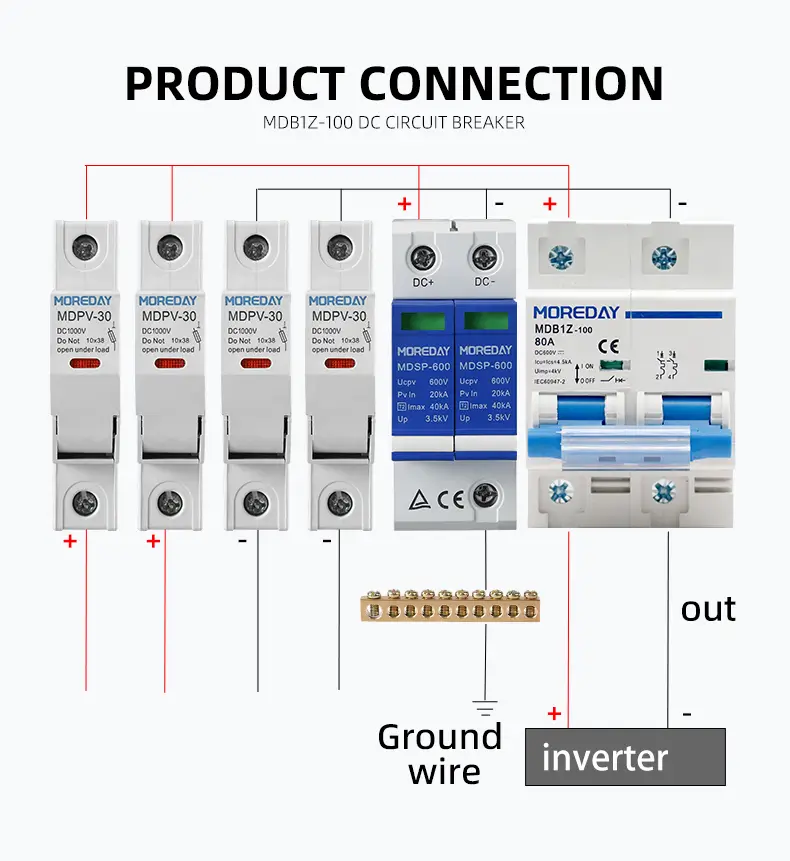

DC breakers are commonly used in solar power generation systems to protect photovoltaic panels and energy storage systems. In addition, DC breakers also play a key protective role in electric vehicles (EVs) and their charging infrastructure.

Communications equipment and data centers are also increasingly using DC power supply, which further increases the demand for high-performance DC circuit breakers.

1. DC circuit breaker structure and design

DC circuit breakers need to take special consideration of the arc extinguishing problem of DC power in their design. The arc of DC power lasts longer, so DC circuit breakers usually use higher contact spacing and special magnetic blowing technology to effectively cut off the DC arc.

Contact material selection and heat dissipation design are also important considerations in DC circuit breakers to ensure their reliability and durability.

2. Advantages of DC breakers

Fast power-off response: DC breakers can quickly disconnect the current when an overload or short circuit is detected, preventing equipment damage and dangerous situations such as fire.

High current carrying capacity: They are generally able to handle higher DC currents and are suitable for high-power DC circuits, such as solar power generation systems and electric vehicle charging stations.

High reliability: Due to the design characteristics of DC circuit breakers, they can maintain stable operation in harsh environments, have a long service life, and have high reliability.

Low maintenance cost: Compared with other types of electrical protection devices, DC circuit breakers have a simple structure, are easy to maintain, and have low maintenance costs.

Modular design: Many DC circuit breakers have a modular design, which can be flexibly configured according to different application requirements and have strong adaptability.

Specialized for DC power: Compared with traditional AC breakers, they have more advantages in handling DC arcs, can effectively extinguish arcs, and avoid the dangers of arcs.

3. Disadvantages of DC breakers

Higher price: Due to the special design and material requirements of DC breakers, their prices are usually higher than traditional AC circuit breakers.

Complex arc extinguishing technology: The characteristics of DC arcs are different from those of AC arcs, so DC circuit breakers require more complex arc extinguishing technology, which may increase design complexity and manufacturing costs.

Large size: Some types of DC circuit breakers may be larger and occupy more installation space due to their arc extinguishing and heat dissipation requirements.

Applicability restrictions: DC circuit breakers are mainly suitable for DC circuits, not AC circuits, so there are certain limitations in diversified application environments.

High installation requirements: Since DC circuit breakers handle DC, their installation and wiring requirements are high, especially in high-voltage applications, requiring professional installation and maintenance personnel.

Through the above analysis of advantages and disadvantages, the application of DC circuit breakers in DC circuits is particularly important, especially in scenarios with high safety and reliability requirements, such as photovoltaic power generation, electric vehicle charging, and other fields.

AC circuit breakers

AC breakers are used to protect AC circuits. They rely on the natural zero crossing of AC to help extinguish the arc, so that the arc is naturally extinguished when the AC passes through zero. This feature makes the AC breaker relatively simple in design and easy to extinguish the arc.

The main function is to automatically cut off the current when an overload, short circuit, or other fault occurs in the circuit, thereby protecting the circuit and equipment from damage. AC circuit breakers are widely used in home, commercial, and industrial power systems to prevent electrical fires, equipment damage, and other safety hazards by disconnecting the current.

1. Structure and design of AC circuit breakers

AC circuit breakers usually include multiple contacts and an arc extinguishing grid to effectively cut off the AC arc. Its contact design and material selection are designed to maximize the arc extinguishing effect and extend the service life of the equipment. AC breakers can also enhance arc extinguishing performance by adding an arc-blowing device.

2. Advantages of AC circuit breakers

Quick response: AC breakers can quickly disconnect the current when circuit abnormalities are detected, providing rapid protection and effectively preventing electrical equipment damage and fire hazards.

Wide range of applications: Applicable to AC circuits of various voltage levels and current ranges, from low-voltage household electricity to high-voltage industrial electricity.

Mature design and high reliability: After years of development, AC breakers have mature design technology, high reliability, and stability, and are suitable for various complex power environments.

Easy to maintain: Due to the relatively simple structure of AC breakers, the failure rate is low, the maintenance cost is low, and most parts are easy to replace.

Strong arc extinguishing ability: Modern AC breakers usually use advanced arc extinguishing technology, such as air arc extinguishing, vacuum arc extinguishing, or SF6 gas arc extinguishing, which can effectively eliminate arcs and improve safety.

Multiple types available: There are many types of AC circuit breakers, such as miniature circuit breakers, molded case circuit breakers, frame circuit breakers, etc., and suitable products can be selected according to different application scenarios and needs.

Modularity and scalability: Many AC breakers have modular designs, which can be quickly configured and upgraded according to the expansion or changes of the power system.

3. Disadvantages of AC circuit breakers

Large price difference: Although AC circuit breakers are widely used, the price difference between different types and specifications of circuit breakers is large, especially since high-performance circuit breakers are more expensive.

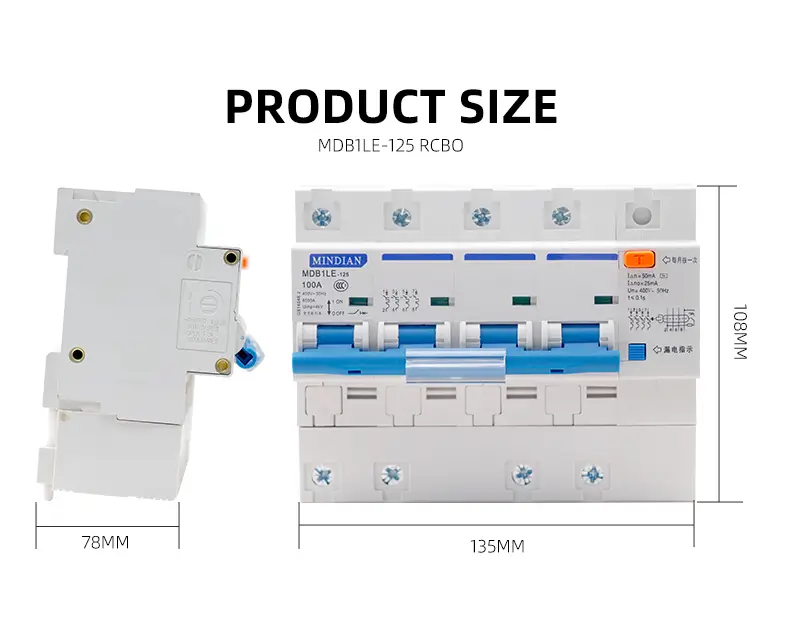

Size and installation space requirements: Some types of AC circuit breakers (such as high-voltage circuit breakers) are large and require high installation space, which may not be suitable for occasions with limited space.

Limited DC application capabilities: AC circuit breakers are mainly designed for AC circuits and cannot effectively handle DC arcs, so their application in DC circuits is limited.

Switching operation complexity: In high-voltage systems, the switching operation of AC circuit breakers may require special equipment and training, which increases the complexity of operation and maintenance.

Periodic testing and calibration may be required: To ensure that AC breakers can work properly in the event of a fault, regular testing and calibration are usually required, which increases the maintenance workload.

Environmental impact: The arc extinguishing medium (such as SF6 gas) used by some AC circuit breakers has a certain impact on the environment and requires environmental protection measures to be taken for treatment and recycling.

In general, AC circuit breakers provide reliable and effective electrical protection in AC circuits and are indispensable equipment in modern power systems. When choosing, users should make reasonable choices based on specific application requirements, environmental conditions, and economic budgets.

Comparative analysis of DC circuit breakers and AC circuit breakers

In this section, we will list a table to compare the differences between DC and AC circuit breakers, including current type, arc extinguishing capability, response time and reliability, cost, and maintenance. As shown in the following table:

| Characteristic | DC Breaker | AC Breaker |

| Arc Extinguishing Capability | Stronger, designed more complexly to handle the persistence of DC arcs | Relatively weaker, as AC arcs can naturally extinguish at zero crossings |

| Design Complexity | Higher, usually requires larger arc chambers and stronger insulation materials | Lower, with simpler designs suitable for various voltage and current levels |

| Application Range | Limited to DC circuits, such as solar systems, battery systems, EV charging, etc. | Widely used in all AC power systems, including residential, commercial, and industrial |

| Maintenance Needs | Higher, often requires regular inspection and maintenance, especially in high-voltage DC applications | Relatively simple maintenance, widely used, and easy to service |

| Cost | Higher, due to complex design and manufacturing, especially in high-voltage DC applications | Varies widely, lower in low-voltage systems, potentially higher in high-voltage systems, but generally lower than DC breakers |

| Installation Requirements | Complex, especially for high-voltage DC systems, with higher installation and commissioning requirements | Relatively simple, easy to install in various AC power systems |

| Suitability | Limited to DC circuits | Suitable for all AC circuits |

The choice of a DC circuit breaker or AC circuit breaker depends on the specific application requirements, circuit type, and environmental conditions. In a DC and AC mixed system, it may be necessary to use both circuit breakers to ensure comprehensive power protection.

How to choose the right circuit breaker?

Choosing the right circuit breaker is a critical task because it is directly related to the safety and reliability of the electrical system.

When choosing a circuit breaker, you need to consider multiple factors, including circuit type, load characteristics, installation environment, etc. The following is a detailed guide to choosing the right circuit breaker:

1. Determine the circuit type

Direct current (DC) circuit: If the circuit to be protected is a DC circuit, such as a solar photovoltaic system, battery storage system, electric vehicle charging station, etc., a DC circuit breaker should be selected. DC circuit breakers are designed for DC power and can effectively handle DC arcs and provide reliable protection.

Alternating current (AC) circuit: If the circuit is an AC circuit, such as household electricity, commercial electricity, or industrial power systems, an AC circuit breaker should be selected. AC circuit breakers are suitable for overload and short-circuit protection in AC circuits, and the design is more diverse.

2. Evaluate current and voltage levels

Rated current (Rated Current, In): When selecting a circuit breaker, it must be determined that its rated current should be greater than or equal to the normal operating current of the circuit. The rated current refers to the maximum continuous current that the circuit breaker can withstand without tripping. Common rated current specifications are 16A, 32A, 63A, etc.

Rated voltage (Rated Voltage, Ue): The rated voltage of the circuit breaker must be greater than or equal to the operating voltage in the circuit. The rated voltage of AC circuit breakers is usually 220V, 380V, 400V, etc., while DC circuit breakers may require higher voltage levels, such as 48V, 110V, 220V, 1000V, etc.

3. Reacting Capacity, Icu/Ics)

The short-circuit breaking capacity is the maximum current value that the circuit breaker can safely cut off when a short circuit occurs.

When selecting, make sure that the breaking capacity of the circuit breaker is greater than or equal to the maximum short-circuit current that may occur in the circuit to ensure safety. Common short-circuit breaking capacities are 6kA, 10kA, 16kA, etc.

4. Choose the appropriate type of circuit breaker

Choose the appropriate type of circuit breaker according to the installation scenario and needs:

Miniature circuit breaker (MCB): Suitable for overload and short-circuit protection in low-voltage systems, such as home and small commercial circuits. Usually used in circuits with a rated current not exceeding 125A.

Molded case circuit breaker (MCCB): Suitable for systems with medium current and voltage, such as industrial equipment and distribution boards. Its rated current can be up to 1000A, suitable for higher current and higher breaking capacity requirements.

Frame circuit breaker (ACB): used for high current and high voltage applications, such as power distribution systems in large industrial and commercial facilities. Its rated current is usually over 1000A, and its breaking capacity and electrical life are high.

Residual current circuit breaker (RCD/RCBO): used to prevent leakage and ground faults, and can cut off the circuit when leakage current is detected. Suitable for occasions where leakage protection is required, such as humid environments or personal safety protection.

5. Consider environmental factors

Temperature: The rating of the circuit breaker is usually based on the standard ambient temperature (usually 30°C). In high or low-temperature environments, the performance of the circuit breaker may be affected, and the temperature correction factor needs to be considered when selecting.

Humidity and corrosive environment: In humid or corrosive environments, circuit breakers with waterproof and anti-corrosion properties should be selected, such as circuit breakers with IP protection ratings.

Vibration and shock: In environments with vibration or mechanical shock, such as industrial machinery or transportation equipment, circuit breakers with anti-vibration characteristics should be selected.

6. Consider the installation method and space

Installation method: Determine whether the circuit breaker is installed in the distribution cabinet or on the wall, or whether it needs to be installed on a DIN rail, etc. Different installation methods require different installation accessories and designs.

Space requirements: Select a circuit breaker of the appropriate size according to the space size of the installation location. Some types of circuit breakers may be larger and require more installation space.

7. Compliance with industry standards and certifications

Choose circuit breakers that comply with relevant national and international standards, such as IEC, UL, GB, and other standards. These standards specify the design, performance, and safety requirements of circuit breakers to ensure their reliability and safety under specific conditions.

9. Cost and brand selection

Cost: Choose the circuit breaker with the highest cost performance while meeting functional and safety requirements. Although high-quality circuit breakers are more expensive, they are generally more reliable, have a longer service life, and lower maintenance costs.

Brand and supplier selection: Choose a reputable brand and a reliable supplier to ensure the quality and after-sales service of the circuit breaker.

When selecting a circuit breaker, it is best to consult an electrical engineer or power system designer to ensure that the selected circuit breaker meets all safety, technical, and regulatory requirements. You can more accurately select the circuit breaker that suits your specific needs and ensure the safe and reliable operation of the power system.

MOREDAY provides professional services

MOREDAY provides professional services for AC and DC circuit breakers. Its products are designed to meet the highest safety and reliability standards and can meet a wide range of application needs.

To choose the right circuit breaker for your application, please contact our sales staff online and we have professional staff to answer your questions.

Related reading: How to test a circuit breaker?