Table of Contents

ToggleIntroduction

Electric vehicles (EVs) have become an integral part of the automotive landscape, revolutionizing the way we think about transportation. One crucial aspect of the EV ecosystem is the charging infrastructure. In this article, we will delve into the EV charger Structure and Principles, exploring the various types, components, working principles, and the future of this essential technology.

Currently, there are four main charging piles in the world: GB/T standard, European standard, American standard, and Japanese standard. According to different charging speeds, they are divided into AC charging and DC charging. We will discuss in depth the EV charger Structure and Principles.

AC VS. DC Charging

In the realm of electric vehicle (EV) charging,AC and DC EV charger Structure and Principles have a big difference understanding the nuances between Alternating Current (AC) and Direct Current (DC) charging is crucial. Each method comes with its advantages and limitations, impacting the efficiency and speed of the charging process.

EV Charger Structure and Principles are divided into AC EV Chargers and DC EV Chargers. The former is also called “slow charging” and the latter is also called “fast charging”.

AC Charging: The Household Connection

AC EV Charger principle is akin to plugging your electric vehicle into a standard household outlet. These Level 1 chargers are ubiquitous and can be found in homes, workplaces, and public spaces. They provide a convenient, albeit slower, method of replenishing your EV’s battery.

AC charging involves converting the alternating current from the power grid to direct current for the vehicle’s battery. The charging cable is equipped with a built-in charger, often located onboard the vehicle, responsible for this conversion process.

While convenient for overnight charging, AC chargers are not known for their speed. Level 1 chargers typically deliver around 2 to 5 miles of range per hour of charging, making them suitable for daily commuting needs but less practical for long journeys.

Homeowners often opt for Level 2 AC chargers, which operate at 220-240 volts. These chargers significantly reduce charging times compared to Level 1, offering a compromise between convenience and speed.

DC Charging: The Need for Speed

DC fast EV chargers, on the other hand, are the speed demons of the charging world. These chargers directly supply DC power to the vehicle’s battery, bypassing the need for onboard conversion. This results in significantly faster charging times compared to their AC counterparts.

DC charging excels in providing rapid energy transfer, making it the preferred choice for public charging stations and long-distance travel. These chargers are commonly found along highways and in busy urban areas.

DC fast chargers can deliver a substantial charge in a short amount of time. Depending on the charger’s power level and the vehicle’s capacity, drivers can gain hundreds of miles of range in just 30 minutes.

While DC fast chargers offer impressive speed, not all electric vehicles are equipped to handle the high power levels they provide. Some vehicles might need additional adapters or have limitations on the charging speed they can accept.

AC EV Charger Structure And Principles

AC EV Charger Principle

The electric vehicle’s AC charging station serves as a dedicated power supply unit affixed externally to the vehicle, linked to the power grid. Its primary function is to furnish AC power to the on-board charger within the electric vehicle, the charger being a fixed installation on the vehicle itself. It’s crucial to note that AC charging stations solely deliver power output and lack inherent charging capabilities.

To charge electric vehicles, they must be connected to a compatible car charger, essentially serving as a power supply control mechanism. AC charging can be categorized into single-phase AC and three-phase AC based on the number of charging phases.

AC EV Charger Structure

The 7KW AC EV charger comprises essential components, including the charger body, LED indicator board, LCD display, card reader, auxiliary power supply, main control module, relay module, wiring strip, single-phase circuit breaker (air switch), surge protector (lightning prevention device), smart meter, AC contactor, access control switch, emergency stop switch, charging gun, and charging harness.

Notably, single-phase 220V 7KW charging guns feature 7 holes and 5 contact terminals. It’s worth mentioning that high-power charging connectors, like three-phase 380V 22KW charging connectors, are equipped with 7 full contact terminals.

DC EV Charger Structure And Principles

DC EV Charger Principle

The DC charging station functions as a stationary power supply unit positioned externally to the electric vehicle and linked to the AC power grid. Its primary purpose is to furnish DC power to the electric vehicle’s off-board power battery. Operating on three-phase four-wire AC with a voltage range of 380V ±15% and a frequency of 50Hz, the DC charging station rectifies the input through internal control. The output is adjustable DC, facilitating direct charging of the electric vehicle’s power battery. Common power capacities for DC charging stations include 30KW, 60KW, 90KW, and 120KW.

DC EV Charger Structure

A 120KW charging station typically comprises essential components such as an LED indicator board, LCD display, card reader, six 20kw charging module or four 30KW charging module, wireless network module, switching power supply, main control board, anti-reflection board, electronic lock, fuse, ammeter, (A+) air switch, leakage circuit breaker, lightning arrester, single-phase air switch, shunt, cooling fan, and more. This comprehensive assembly ensures the effective and secure operation of the high-capacity charging station.

Charger enclosure: Typically, the DC EV Charger Structure enclosure is crafted from sheet metal steel, aluminum alloy, and other robust materials. This construction imparts significant durability and stability, allowing the charging pile to operate reliably in outdoor environments. Moreover, it boasts waterproof and dustproof performance meeting or exceeding IP54 standards, ensuring resilience against environmental elements.

Charging module: serves as the essential component of the charging station, encompassing chargers, controllers, power supplies, and other vital elements. At the core of the DC EV Charger structure, the charger assumes a primary role, converting electrical energy into the specific power required by electric vehicles. Responsible for overseeing the charger’s operational state and various parameters throughout the charging process, the controller ensures the safety and stability of the overall charging procedure. Simultaneously, the power supply functions to deliver electrical energy to the charging module, completing the integral cycle of the charging station.

Display screen: typically presents information such as the charger status, charging progress, and associated fees. Display screens vary in type and size, with some EV Chargers featuring touch screens for user convenience, facilitating human-computer interaction, and catering to the diverse preferences of users. The integration of built-in charging pile software enables the implementation of operational functions, enhancing the station’s overall capabilities.

Account management system: Accurately computing the current consumption cost involves leveraging real-time electricity prices, electricity usage data, and charging fees, followed by generating and printing bills. This accounting management process necessitates seamless collaboration between the controller and the embedded printer. Charging operations adhere to a trapezoidal electricity pricing and time policy. The internal controller performs the intricate task of calculating the consumption cost and finalizing the charging process. Subsequently, the controller communicates with the embedded printer, transmitting consumption information for the printing of detailed charging bills. This integrated system ensures efficient and transparent billing for the charging process.

Charging cable: Cables serve as the crucial link between charging stations and electric vehicles, is also an integral part of the EV Charger structure.It tasked with both power and data transmission. The efficiency and safety of the charging process are directly impacted by the quality and length of the connecting cable. Typically, opting for charging cables from reputable brands with relevant certifications is a standard practice. In addition, some high-end charging stations feature automatic cable retractors, enhancing user convenience and further streamlining the charging experience.

Safety protection device: Safety safeguards for charging stations encompass crucial features like leakage protection, overcurrent protection, overvoltage protection, lightning protection, and more. These safety protection devices are also important factors affecting the EV Charger structure. The integration of these protective devices is imperative to ensure the effective and comprehensive safety of both the charging station and the electric vehicles undergoing charging processes.

How EV Chargers work?

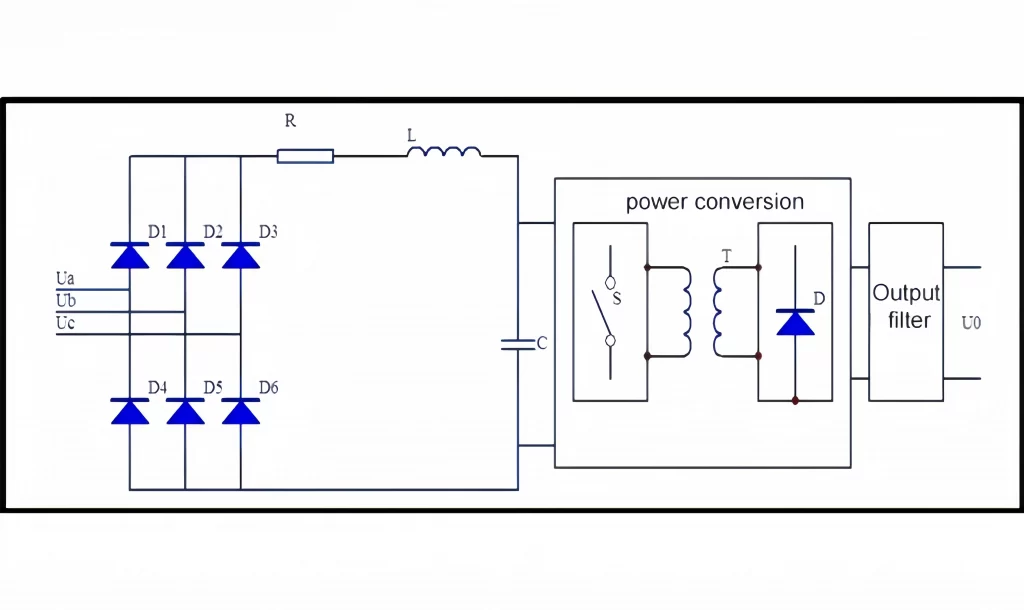

AC power is drawn from the three-phase power grid and undergoes conversion to DC power through an uncontrollable rectifier circuit. Following filtration by the LCR circuit, the power is directed to a high-frequency DC-DC power converter. This converter, through direct-to-DC conversion, produces the necessary DC voltage, which is further refined through output filtration before charging the electric car battery. The charging system offers four distinct modes: fixed quantity, fixed time, fixed amount, and automatic (continues until full charge).

In essence, the operational EV Charger principle revolves around the integration of the power supply, converter, and output device. This combination serves to elevate the voltage from a low to high state, transforming the high voltage into a usable power supply, ultimately facilitating the charging process for electric vehicles.

In Conclusion

Understanding the EV Charger Structure And Principles is pivotal in grasping the technology propelling the burgeoning electric transportation sector. At its core, an electric vehicle charger comprises essential components like the charging cable, plug, and the integral control unit. Charging stations, on a broader scale, encompass power electronics, control systems, charging modules, and communication modules.

Power electronics play a crucial role, converting alternating current from the grid into direct current suitable for the vehicle’s battery. Simultaneously, the control system adjusts variables such as voltage and current to ensure safe and efficient charging. The communication module facilitates data exchange between the charger, vehicle, and potentially external networks, enabling smart charging functions and monitoring.

Guided by EV Charger Structure And Principles emphasizing safety, efficiency, and interoperability, the design of electric vehicle chargers aims to deliver a seamless charging experience, contributing to the broader objectives of sustainable and eco-friendly transportation. As technology evolves, ongoing innovations in the structure and principles of electric vehicle chargers hold the potential to shape the future landscape of electric vehicles.

Common Queries

Frequently Asked Questions

please feel free to contact us.

A: An EV charger consists of three main components – the power supply unit, the charging connector, and the control unit. The power supply unit converts AC power from the grid into DC power suitable for charging electric vehicles. The charging connector physically links the charger to the vehicle, while the control unit manages the charging process, ensuring safety and optimal performance.

A: EV chargers and electric vehicles communicate through a standardized protocol known as the Charging Communication Control Unit (CCCU). This protocol allows for the exchange of information between the charger and the vehicle, such as charging power, battery status, and authentication data. Common standards include CHAdeMO, CCS (Combined Charging System), and Type 2.

A: The charging speed of an EV charger is influenced by factors like the charger’s power output, the vehicle’s maximum charging capacity, and the state of the vehicle’s battery. Generally, higher power chargers deliver faster charging times, but the vehicle’s onboard charging system and battery condition play crucial roles in determining the actual charging speed.

A: Yes, there are various types of EV chargers categorized by their power levels and charging connectors. Level 1 chargers operate on standard household outlets and provide low power. Level 2 chargers offer higher power and are commonly found in residential and public charging stations. DC fast chargers, classified as Level 3, provide even higher power and are suitable for rapid charging in commercial settings. The charging connectors also vary based on regional standards.

A: EV chargers incorporate multiple safety features to ensure secure charging operations. These include overcurrent protection, overvoltage protection, temperature monitoring, and short-circuit protection. Additionally, communication protocols between the charger and the vehicle include authentication processes to prevent unauthorized access or use, enhancing overall safety during the charging process.

Ryan Huang

Hey, I’m Ryan Huang, the founder of Moredaydc.com, an expert in solar electrical products and ev charging.

In the past 15 years, we have helped 60 countries and nearly 500 customers (such as farms, residences, industrial and commercial) solve new energy and green power problems. This article aims to share more knowledge about solar electricity and new energy with everyone, so that green electricity can enter every home.

Make Electricity Available To All People