Table of Contents

ToggleIntroduction

Welcome to our comprehensive guide on fuse holders! If you’re new to the world of electrical circuits and protection, you may be wondering what a fuse holder is and why it’s important. Well, you’ve come to the right place.

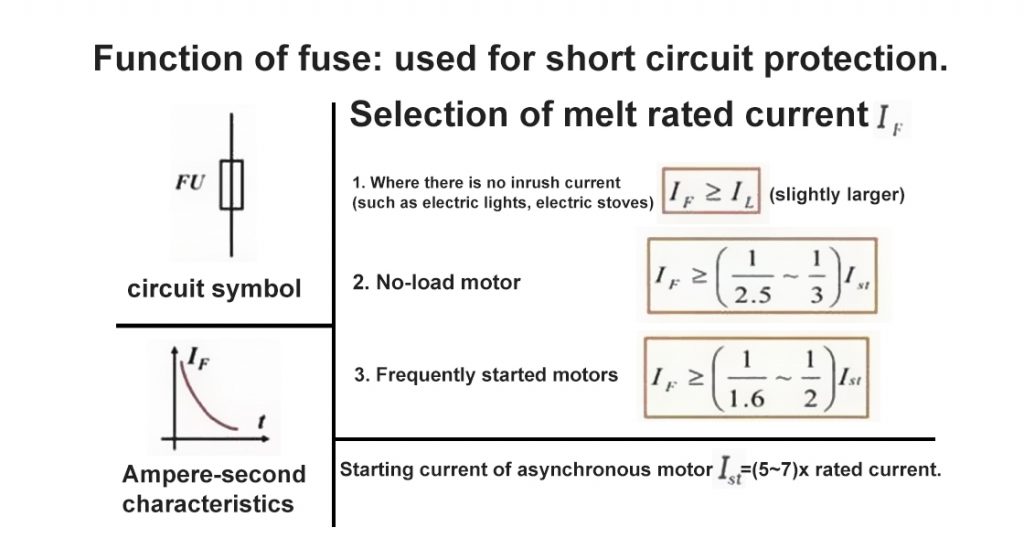

Fuses play a crucial role in safeguarding electrical systems by protecting them from overcurrents and short circuits. They are designed to hold and secure fuses, which are essential components that melt and break the circuit when excessive current flows through them. By doing so, fuses prevent damage to sensitive equipment, minimize the risk of electrical fires, and ensure the safety of both people and property.

In this guide, we will walk you through everything you need to know about fuse holders. We will explore the different types of fuse holders available, discuss the factors to consider when selecting the right one for your application, and provide tips on installation and maintenance. Additionally, we will address common issues that may arise with fuse bases and offer troubleshooting advice.

Whether you’re a DIY enthusiast or a professional electrician, this guide will equip you with the knowledge and understanding necessary to make informed decisions when it comes to fuses. So, let’s dive in and explore the world of fuse holders together!

Understanding Fuse Holders

Fuse holders are an essential component in electrical systems, providing protection against overcurrent and preventing damage to equipment. Understanding how fuses work is crucial for ensuring the safety and reliability of your electrical circuits.

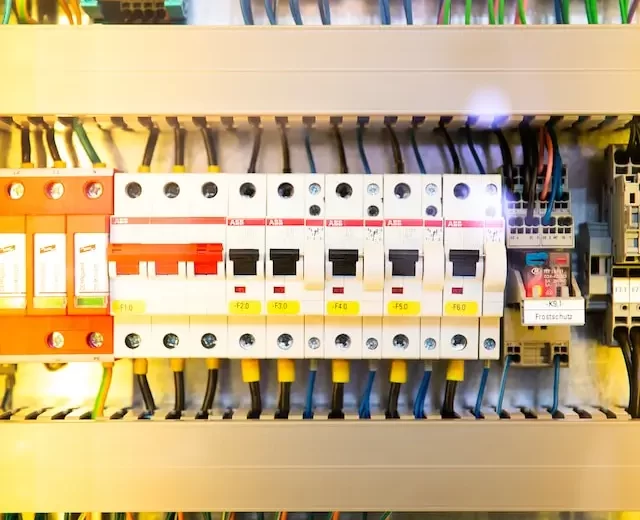

Fuse bases come in various types, including panel-mounted, inline, and blade fuse bases. They are designed to hold and secure fuses, which are devices that melt when exposed to excessive current, interrupting the circuit and protecting the connected equipment.

Another factor to consider is the voltage rating of the fuse holder. This value indicates the maximum voltage that the fuse can safely handle. It is crucial to select a fuse holder with a voltage rating equal to or higher than the voltage of your electrical system.

Fuses also differ in their mounting configurations and connector types. Some fuse can be mounted on panels or DIN rails, while others have specific connector types for different wire terminations. Choosing the right mounting configuration and connector type ensures a secure and reliable connection.

Proper installation and maintenance of holders are essential for their effective operation. It is crucial to follow the manufacturer’s instructions and guidelines when installing holders. Regular inspections and replacements of fuses are necessary to ensure continuous protection.

In conclusion, understanding fuse holders is vital for maintaining the safety and reliability of electrical systems. Consider factors such as rated current, voltage rating, mounting configuration, and connector type when selecting a fuse holder. Proper installation and maintenance practices will ensure the optimal performance of fuse holders in protecting your electrical circuits.

Types of Fuse Holders

When it comes to fuse holders, there are several different types to choose from, each designed to meet specific needs and requirements. Understanding the various types can help you select the right fuse holder for your application.

Blade Fuse Holders: These are the most common types of holders and are widely used in automotive and marine applications. They are designed to hold ATO/ATC blade fuses and provide a secure and reliable connection.

Panel Mount Fuse Holders: As the name suggests, these are designed to be mounted on panels or surfaces. They are commonly used in industrial and electrical applications, where easy access to the fuse is required.

Inline Fuse Holders: These holders are designed to be installed directly into a wire, providing protection for a specific circuit. They are commonly used in automotive and electronic applications.

Waterproof Fuse Holders: These fuse holders are specifically designed to be moisture-resistant, making them ideal for use in marine or outdoor applications. They provide reliable protection for fuses in wet or humid environments.

PCB Mount Fuse Holders: These fuse holders are designed to be mounted directly onto a printed circuit board (PCB). They are commonly used in electronic devices and provide a compact and space-saving solution.

DIN Rail Mount Fuse Holders: They are designed to be mounted on DIN rails, which are commonly used in industrial control panels. They provide a convenient and organized way to mount and secure fuses.

It is important to choose the right type of fuse holder based on your specific application and requirements. Consider factors such as the voltage and current rating, mounting options, and environmental conditions to ensure the proper functioning and protection of your electrical system.

Factors to Consider in Fuse Holder Selection

When selecting a true holder, there are several important factors to consider to ensure the right choice for your specific application. Here are some key considerations to keep in mind:

1. Accessibility and Replacement

One of the first questions to ask is whether the fuse needs to be easily accessible for replacement. If frequent fuse changes are expected, it is important to choose a fuse holder that allows for easy removal and replacement of the fuse. On the other hand, if the fuse is not expected to be replaced often, a more secure and enclosed fuse may be suitable.

2. End Customer Access

Consider whether the end customer of the appliance should have access to change the fuse. If the fuse link is located in a consumer-facing appliance, it may be necessary to choose a fuse link that allows for easy access and replacement by the end user. However, in some cases, it may be preferable to restrict access to the fuse holder to trained technicians only.

3. Safety and Reliability

The amount you are willing to spend on safety and reliability is an important factor in fuse selection. Higher-quality fuse holders may offer better protection against electrical faults and ensure reliable performance over time. It is worth considering the long-term costs associated with potential fuse failures and the impact they may have on your equipment or system.

4. Compliance with Standards

Different standards exist for fuse holders, such as IEC-publication 257 and UL-standard no. 512. It is important to understand the differences between these standards and ensure that the chosen fuse holder meets the necessary requirements for your specific application. Compliance with one standard does not necessarily mean compliance with the other, so careful evaluation is needed.

5. Rated Current and Power Dissipation

The rated current and power dissipation of the fuse bases are critical factors to consider. The rated current determines the maximum current that the fuse base can handle without exceeding temperature limits. The power dissipation indicates the amount of power the fuse base can accept under prescribed conditions. It is important to select a fuse holder with the appropriate rated current and power dissipation for your specific fuse type and application.

By carefully considering these factors, you can ensure that the fuse you choose meets the requirements of your application, providing reliable and safe protection for your electrical system.

Installation and Maintenance of Fuse Holders

Installing and maintaining holders is essential for ensuring the safety and reliability of electrical systems. Here are some key points to consider:

Proper Installation

- Before installing a holder, carefully read the manufacturer’s instructions to ensure proper installation.

- Choose a suitable location for the holder, considering factors such as accessibility, protection from environmental elements, and ease of maintenance.

- Follow the recommended wiring practices to ensure secure and proper connections.

- Use the appropriate tools and techniques to install the fuse holder, ensuring that all connections are tight and secure.

Regular Inspection and Maintenance

- Regularly inspect the fuse for any signs of damage, such as cracks, corrosion, or loose connections. Replace any damaged components immediately.

- Check the holder for proper alignment and ensure that it is securely mounted.

- Clean the holder periodically to remove any dirt or debris that may affect its performance.

- Test the fuse periodically to verify its functionality. This can be done by using a multimeter or consulting a qualified electrician.

Fuse Replacement

- Follow the manufacturer’s guidelines for fuse replacement, including the type and rating of the fuse to be used.

- Ensure that the power supply is disconnected before replacing a fuse to avoid electrical shock.

- Use only fuses that meet the required specifications and are compatible with the fuse holder.

- Carefully insert the new fuse into the holder, ensuring that it is properly seated and making good contact.

By following these installation and maintenance practices, you can ensure the proper functioning of your holders and enhance the safety and reliability of your electrical system. Remember to consult a qualified professional if you have any doubts or concerns.

Common Issues and Troubleshooting

When it comes to fuse holders, there are a few common issues that can arise. However, with some troubleshooting tips, you can easily resolve these problems and ensure the proper functioning of your fuse holder.

Blown Fuses

One of the most common issues with fuze holders is blown fuses. This can happen due to overloading or a short circuit. To troubleshoot this issue, start by checking the fuse rating and make sure it matches the requirements of your circuit. If the fuse keeps blowing, it may be a sign of a larger electrical problem that needs to be addressed.

Loose Connections

Another common issue is loose connections within the fuze holder. This can lead to intermittent power supply or even complete failure. To fix this problem, ensure that all connections are tight and secure. You can use a screwdriver or pliers to tighten the terminals if necessary.

Corrosion

Over time, corrosion can build up on the terminals of the fuze holder, leading to poor conductivity. To address this issue, clean the terminals using a wire brush or sandpaper. Make sure to remove any debris or oxidation that may be present. Additionally, consider using a corrosion-resistant fuze holder to prevent future corrosion.

Faulty Fuze Holder

In some cases, the fuse holder itself may be faulty. This can happen due to wear and tear or manufacturing defects. If you suspect that the fuse holder is the problem, it is recommended to replace it with a new one. Make sure to choose a high-quality fuze holder that meets the requirements of your circuit.

By addressing these common issues and following the troubleshooting tips, you can ensure the proper functioning of your fuse holder. Remember to always prioritize safety and consult a professional if you are unsure about any electrical work.MOREDAY is a company specializing in manufacturing fuses, we can provide professional customization services.

Derek Ke

Hey, I’m Derek Ke, the founder of Moredaydc.com, an expert in solar electrical products and ev charging.

In the past 15 years, we have helped 60 countries and nearly 500 customers (such as farms, residences, industrial and commercial) solve new energy and green power problems. This article aims to share more knowledge about solar electricity and new energy with everyone, so that green electricity can enter every home.

Make Electricity Available To All People