Direct current (DC) circuit breakers are essential components in electrical systems that operate on DC power. Unlike alternating current (AC) breakers, DC breakers are designed to handle continuous and unidirectional currents.

choosing the right DC circuit breaker ensures system protection, reliability, and efficiency. This article will guide you through the key factors to consider when selecting a DC circuit breaker for your application.

Table of Contents

ToggleWhat is DC Circuit Breakers?

A DC circuit breaker is designed to interrupt electrical faults and protect circuits from damage caused by overcurrent conditions. They are commonly used in solar power systems, electric vehicles, telecommunications, industrial machinery, and railway applications.

Unlike AC circuit breakers, which can leverage the natural zero-crossing of AC signals to interrupt currents, DC breakers require specialized arc-extinguishing techniques due to the continuous nature of DC flow.

Factors to Consider When Choosing a DC Circuit Breaker

1. Voltage Rating

The voltage rating of a DC circuit breaker is a crucial parameter. It defines the maximum voltage the breaker can handle without arcing or insulation failure. When selecting a breaker, consider the system’s operating voltage and ensure the breaker’s rating meets or exceeds this value.

DC voltages are often higher in applications like solar power (e.g., 48V, 100V, 600V, or even 1500V), so choosing the right circuit breaker can also effectively improve our safety and efficiency issues.

2. Current Rating

The current rating (measured in amperes, A) specifies the maximum continuous current the breaker can handle without tripping. Choosing the correct current rating ensures that normal operation is uninterrupted while protecting the circuit from overcurrent conditions. To determine the right rating:

- Calculate the normal operating current.

- Consider potential overload conditions.

- Add a safety margin (typically 20-25%) to prevent nuisance tripping.

3. Breaking Capacity (Interrupting Rating)

Breaking capacity refers to the maximum fault current the breaker can safely interrupt without damage. In DC circuits, breaking an electrical fault is more challenging due to the absence of natural current zero-crossing.

High-energy DC arcs can be difficult to extinguish, making it necessary to choose a breaker with an adequate interrupting rating. Consider the maximum possible short-circuit current in your system and ensure the breaker’s interrupting capacity is sufficient.

4. Trip Mechanism

DC circuit breakers use different trip mechanisms to detect and respond to overcurrent conditions. The common types include:

Thermal-magnetic breakers: Use a bimetallic strip (thermal) for prolonged overload protection and an electromagnet (magnetic) for instantaneous trips under short-circuit conditions.

Electronic breakers: Use microprocessors to provide precise control and adjustable trip settings, often used in advanced DC applications.

Hydraulic-magnetic breakers: Suitable for harsh environments and provide consistent performance regardless of ambient temperature variations.

5. Number of Poles

Depending on your system configuration, you may need a single-pole or multi-pole DC circuit breaker:

Single-pole breakers: Used for lower voltage applications, such as 12V or 24V DC systems.

Two-pole or four-pole breakers: Common in higher voltage applications where series-connected poles help in arc suppression.

6. Application-Specific Considerations

Different applications require different types of DC circuit breakers:

Solar power systems: Require high-voltage DC breakers (600V–1500V) with arc-extinguishing features.

Electric vehicles (EVs): Demand compact, high-performance breakers capable of handling high DC currents.

Telecommunications: Use 48V DC breakers designed for reliability and minimal power loss.

Industrial and railway applications: Require heavy-duty breakers with high breaking capacity.

7. Environmental and Safety Considerations

Ambient Temperature: Some breakers are temperature-sensitive, so select one that operates reliably in your environment.

Enclosure Rating (IP Rating): If the breaker is installed outdoors or in harsh conditions, ensure it has an appropriate IP rating for dust and moisture resistance.

Certifications and Standards: Look for breakers that meet industry standards such as UL 489B, IEC 60947-2, or ANSI C37.

8. Installation and Maintenance

- Ensure the brea- ker is compatible with your panel design and mounting method (DIN rail or bolt-on types).

- Consider ease of reset and maintenance, especially in applications where frequent servicing is required.

- Choose breakers with clear labeling and indications for quick troubleshooting.

Conclusion

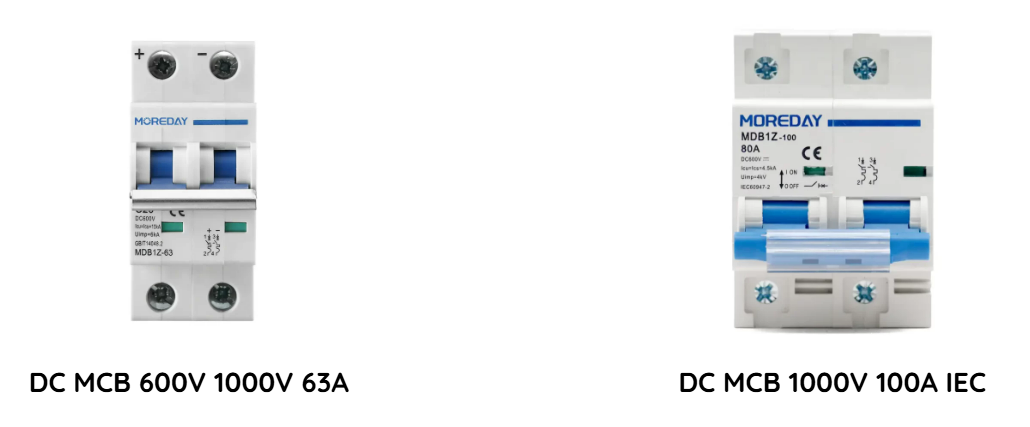

Choosing the right DC circuit breaker can help us ensure the safety and efficiency of electrical systems. Factors to consider when selecting include voltage and current ratings, breaking capacity, tripping mechanism, number of poles, and application-specific requirements.

In addition, environmental factors and compliance with industry standards are also key elements in making a choice. By understanding these factors, I believe you can also make an informed decision to protect your equipment and improve system reliability. If you’re looking for high-quality options, Moreday offers a range of DC circuit breakers available for both wholesale and individual purchase.

FAQ

1. What Is the Difference Between a DC and an AC Circuit Breaker?

DC circuit breakers are designed to handle continuous, unidirectional currents, whereas AC circuit breakers take advantage of the natural zero-crossing of AC currents to interrupt faults more easily. This key difference is central to the discussion of DC breaker vs AC breaker, as DC breakers require stronger arc-extinguishing mechanisms to effectively interrupt the current flow.

2. Can I Use an AC Circuit Breaker for DC Applications?

Most AC circuit breakers are not suitable for DC applications due to the continuous nature of DC currents, which makes arc extinction difficult. Always use a breaker specifically rated for DC voltage and current.

3. How do I Determine the Right Voltage Rating for my DC Circuit Breaker?

Choose a breaker with a voltage rating equal to or greater than your system’s maximum DC voltage. Consider voltage fluctuations and ensure compliance with safety standards.

4. Why Does Breaking Capacity Matter in DC Circuit Breakers?

Breaking capacity determines the maximum fault current the breaker can interrupt without damage. DC arcs are harder to extinguish, so selecting a breaker with an adequate breaking capacity prevents damage and enhances safety.

5. What Maintenance is Required for DC Circuit Breakers?

Regularly inspect for signs of wear, overheating, and arc damage. Clean contacts if necessary and ensure the breaker operates within its rated parameters. Follow manufacturer guidelines for periodic testing and maintenance.

Related reading: Does Resetting AC Breaker Help?